KUBOTA GIANNI FERRARI

The PG/SR range is made up of some of Gianni Ferrari’s most well-known and widely used multi-function work machines, in 3 main versions: PG, PG XPRO and SR XPRO (without collector).

Versatility and maneuverability are the winning characteristics that bring the range onto different stages such as private gardens, school gardens and camp sites, without forgetting major sporting facilities with natural or synthetic grass.

Compact dimensions, performance and reliability are what make PG/SR the crucial ally of numerous municipalities, optimizing the care and cleaning tasks of public parks and gardens and moving easily on roundabouts, sidewalks and traffic islands.Not even the harshest conditions create an insurmountable obstacle for PG/SR, which can get around even in very high, overgrown grass in large rural areas, snowdrifts and ice formation in open spaces, cycle lanes and car parks.

MULTI-FUNCTION

Quick access to the front-mounted attachments, and their outstanding interchangeability, are two significant plus factors that enable the PG/SR range to play a leading role in 4 different sectors (agriculture, gardening, cleaning and snow) with top comfort and performance, whether it’s a question of cutting grass or removing litter, cans and dry leaves, or clearing snowdrifts at the sides of roads and cycle lanes. Characteristics that, at the same time, accentuate the excellent versatility not only of these models but of the whole selection of Gianni Ferrari multifunction vehicles.

The latest Smart System patent on our next generation flail mower – which allows the blades (Y, spoon and vertical) to be changed and combined on-site in less than 15 minutes thanks to the innovative magnet system – boosts the already onsiderable number of attachments for the PG/SR, and ensures that the economic investment is countered by the notable advantage of being able to use the same machine throughout the whole year. The GF3x1 Plus flail mowers with collection are fitted with a reinforced rotor with magnetic blade-locking pins that are impossible to move even if they accidentally come into contact with stones or large bushes. A small hydraulic cylinder, activated by means of a handy button (or an equally practical lever in the manual version), enables perfect mulching and unloading onto the ground; these components, in fact, quickly move a sheet metal guard that isolates or links the cutting rotor area and the area of the collection screw conveyor.

BUILT-IN COLLECTION SYSTEM 4

The PG models are designed as multi-function collection machines. That’s why they have a built-in loading system: the powerful suction turbine, made of a hard-wearing resistant material, and the collection tube,are an integral part of the power unit.This solution makes the PG the only one of its kind on the market, for various reasons:

- the absence of protruding side parts in the form of external collection tubes means it’s highly compact, with unbeatable manoeuvrability even in narrow spaces, all to the benefit of productivity

- the machine is more stable and balanced, thanks to the better positioning of the centre of gravity

- the collection procedure is more effective because the cut grass has to travel a shorter distance so there’s less risk of losing the load

- no clogging of the turbine and collection tube

- exceptional versatility of the machine, as the turbine and collector are always ready to be used with different types of attachment.

Complete technological innovation on the XPRO version, thanks to the possibility to COUPLE and DECOUPLE the suction turbine (regardless of the PTO) as required, for the various attachments mounted on the machine. This has been made possible by special electric actuators commanded from an interface button on the new dashboard on the machine.

CUTTING SYSTEM

All the cutting devices are equipped with solid run-flat rubber wheels and discs with a twin pair of retractable anti-collision blades that absorb any knocks, safeguarding the transmission from impact with foreign bodies on the ground.

The twin cutters prevent the accumulation of grass and soil debris in the upper inside part of the lawn mower body, maintaining an even cutting quality throughout the task and reducing stoppages to clean the equipment.

The same system ensures that the cut material is very finely shredded, improving collection and compaction in the collector.

All the decks are fitted with a transmission with mechanical reducers in ductile cast iron with oil-bath conical helicoidal gears, for a unique level of robustness and reliability.

The lawn mower decks are of the floating type so they adapt perfectly to the slopes in the ground, ensuring precise cutting at all times.

On the 126 and 130 cm decks, the cutting height can be adjusted very quickly with the SA™ system, involving a handy manual spring lever positioned directly on the upper part of the deck.

THE ADVANTAGES OF FRONT CUTTING

- Better cutting quality: the grass is not stepped on before cutting

- Better visibility and comfort for the operator

- Better maneuverability and cutting in areas that cannot be accessed by the midmonth decks

- Better adaptation to the lopes in the ground, for more precise cutting

A front opening in the body makes the edge higher than the cutting level of the blades. This height difference means the grass isn’t crushed so the blade can make an accurate cut even on tall grass, with mobile flaps that open in this case to ensure safety and then close again with short grass or when hit by objects inside.

The 130 RCA lawn mower stands out for the blade rotation direction, which is the opposite of that on traditional lawn mowers. The particular RC™ rotation, combined with the exclusive and purposely designed body, guarantees a cutting quality similar to that of a mower with helicoidal blades plus extremely high hourly productivity.

A 2-point hydraulic lift provides a ramp angle of 40° that’s handy in the case of kerbs and pavements up to 17 cm high, and also facilitates the inspection, cleaning and maintenance of the lower part of the mower.

COLLECTOR

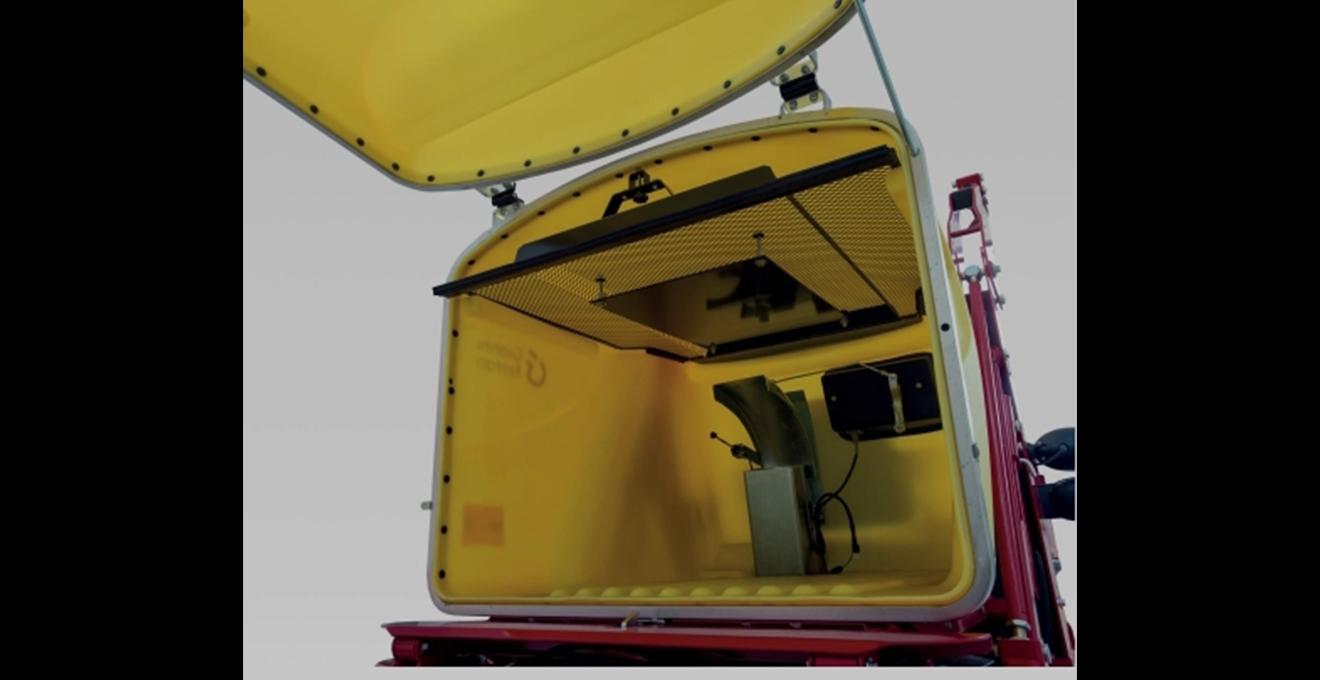

The high-capacity collector is made of polymeric anti-collision material and is fitted with:

- a screen that regulates the air flow during the collection and can easily be removed for cleaning

- a deflector and a motorized rotary load distributor to evenly distribute and compress the grass, exploiting the entire loading space

- a “full collector” buzzer, to prevent it from getting clogged.

Every PG model is available with an elevator for high unloading. Thanks to a hydraulically activated parallelogram system, the cut grass can be unloaded at a height of up to 205 cm into trailers of any size.

An exclusive filter with a self-cleaning function using an electric motor every time the suction turbine is deactivated, minimizes the dispersion of dust and materials collected and is recommended as an optional for the sweeper with collection.

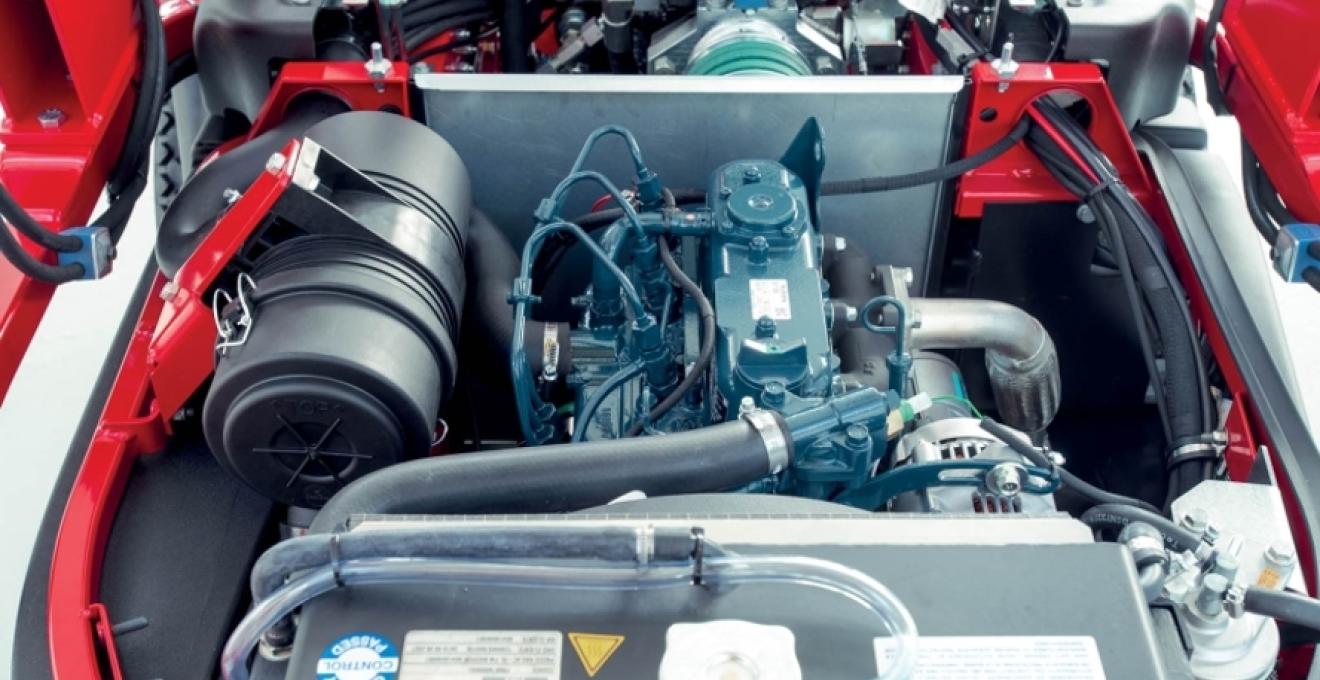

The PG/SR range is fitted with professional Briggs & Stratton twin-cylinder petrol engines and Kubota 3-cylinder diesel engines. Both types fall within Stage V (low emissions), fully respecting anti-pollution legislation. The petrol engines are equipped with an air filter with two filtering elements and a forced lubrication system with an oil filter, to enhance both protection and working life.

For top performance, the diesel engines can count on liquid cooling.

The water/oil radiator, with its anti-clogging fin, is generously proportioned and ensures notable heat exchange even in heavy duty conditions, thus prolonging the lifespan of the engine, oil and hydraulic components. In this case, the filtering system is made up of a self-cleaning cyclonic pre-filter.

The brand new PG 333W BFuel model with a Kubota LPG/petrol engine is another addition to the range.

This particular combination, offered by very few others on the market, aims to meet what has now become a significant need to optimize work costs due to the ever increasing diesel prices. The new version boasts two tanks – 35L (LPG) and 12L (petrol) – to cover the entire working day of a maintenance operator, offering notable savings during transit and when unloading the full collector thanks to the use of LPG alone, yet at the same time ensuring outstanding productivity thanks to the powerful petrol engine. Another factor that shouldn’t be underestimated is the possibility to enter shared public and private work areas, currently off limits to diesel engines. The same model is also available with a Kubota petrol engine only.

| PG | PG 230 | PG 220D | PG 280D | PG 280DW |

| Capacity | 600 L* / 800 L** | 600 L / 800 L | 800 L | 800 L |

| Maximum emptying height | 190 cm | 190 cm | 192 cm | 196 cm |

| Overhang at maximum height | 35 cm | 35 cm | 35 cm | 30 cm |

COLLECTION SYSTEM: Built-in turbine-assisted collection

MATERIAL: Highly resistant polyethylene

CHARACTERISTICS: Removable filtering screen for cleaning, anti-clogging (full load) buzzer and Motorised spreader for full packed load (for 800 L only)

HIGH UNLOADING ELEVATOR: Hydraulic (as standard)

| XPRO RANGE | PG 220 D | PG 280 D | PG/SR 280 DW | PG 333W BFUEL | PG 333W |

| Capacity | 800 L | 800 L | 800 L | 800 L | 800 L |

| Maximum emptying height | 205 cm | 205 cm | 205 cm | 205 cm | 205 cm |

| Overhang at maximum height | 35 cm | 35 cm | 30 cm | 30 cm | 30 cm |

COLLECTION SYSTEM: Built-in turbine-assisted collection that can be disengaged

MATERIAL: Highly resistant polyethylene

CHARACTERISTICS: Removable filtering screen for cleaning, anti-clogging (full load) buzzer and Motorised spreader for full packed load (for 800 L only)

HIGH UNLOADING ELEVATOR: Hydraulic (as standard)

TRANSMISSION

The hydrostatic transmission system is highly efficient thanks to the piston-operated hydraulic motor, and guarantees excellent performance. In difficult conditions such as rough ground, slopes or poor grip, the mechanical differential ensures that all the available axle torque is transmitted to the wheel for better grip and excellent traction at all times.

On all the machines, the front axle consists of a differential unit that connects two oil-bath gear reducers to transmit the drive to the wheels.

The petrol versions of the PG range come with 2 drive wheels only, but the number increases to 4 on the diesel versions with bigger engines (including the SR XPRO).

The 4 drive wheels are accompanied by the exclusive patented HTC™ device (Hydrostatic Traction Control) that guarantees invaluable benefits:

- it prevents the steering wheels from damaging the lawn when steering, eliminating skids caused by the hauling effect

- it guarantees permanent traction on the 4 wheels, which means safety for the operator.

This aspect is something that distinguishes us from the other products on the market which, during steering, have to deactivate the traction on one or two wheels, in practice losing the 4WD advantage that ensures greater safety.

The XPRO version has a twin pedal that regulates forward and reverse movement, while the single pedal of the basic version activates movement in both directions in a quick, user-friendly manner.

ATTACHEMENTS

“INLINE” REAR DISCHARGE/MULCHING DECK

DUAL CUT™ MULCHING/REAR DISCHARGE DECK

MULCHING DECK WITH SIDE DISCHARGE

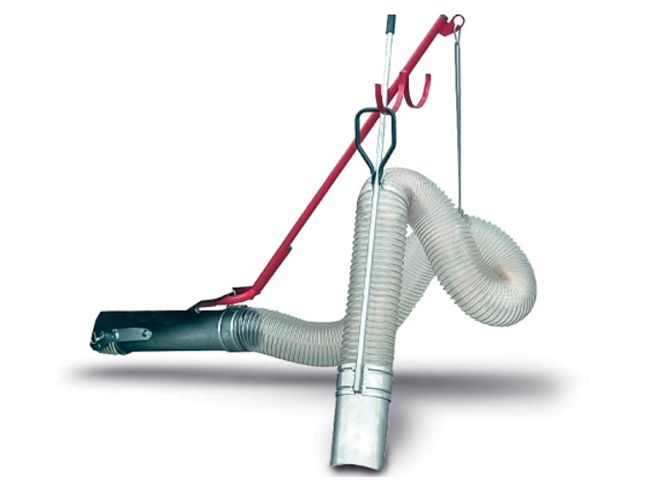

VACUUM HOSE

FLAIL MOWER MFA SMART SYSTEM

FLAIL MOWER WITH COLLECTION GF3X1 PLUS SMART SYSTEM

CLEANING SYNTHETIC GRASS BRUSH

TWO-STAGE COLLECTION SWEEPER

ROTARY SWEEPER

SNOW BLADE

SNOW THROWER

SALT SPREADER